There are two types of battery: primary and secondary. Primary batteries have a limited lifespan producing pre-stored energy and can generally not be recharged. Secondary batteries installed in electric vehicles are rechargeable cells that store electricity once recharged. Batteries are normally positioned down the centre of the chassis with more mass at the rear, to provide better safety and weight distribution. Batteries for electric cars were lead-acid (LA) for over a century, until Nickel Metal Hydride batteries (NiMH) gained favour for their lower weight and high current or charge density. But now, almost all modern electric cars use some variant of lithium battery (Li-ion).

The mass and weight of electric cars has always been a frequent design issue. The battery and electric propulsion system typically account for 40% of the weight of an EV, while in a fossil fuelled car, the engine, coolant system, and ancillary devices only amount to 25% to 30% of the weight of the car, dependant on fuel tank size.

Newer technologies under development, might however deliver alternatives that are more acceptable to the general public and like BEVs, may be zero emission at use too. For instance, fuel cells EVs have a chemical source of either hydrogen, ethanol, methane or even petroleum gasoline that produces electrons that generate electricity to drive the power train. A FCEVs down side is that there is no contiguous national hydrogen filling infrastructure yet in any country and then of course there is the safety aspect. But because the vast majority of fuel cells produce a constant voltage, then they need a pack of batteries to soak up the fuel cells output and store for a more controllable output to power the EV. Lithium batteries are now the ‘de-facto’ battery of EV choice, but their success may still be hampered by limited supplies of raw materials needed to cope with the huge demand on battery manufacturers as the world heads for a green, carbon free future.

Lithium batteries

There are 5 main lithium technologies in common use on EVs today, with two of these used in most electric cars, Lithium Nickel Manganese Cobalt (NMC) and Lithium Iron Phosphate (LFP). The following section focuses solely on lithium technology used in EVs and highlights how a simple lithium cell charges and discharges, summarising the main lithium chemistries, strengths, weaknesses and features.

How a lithium battery works

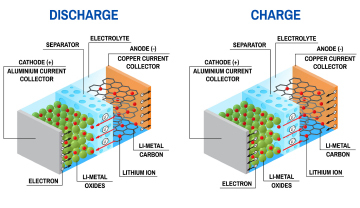

The diagram below illustrates the basic function of how a lithium battery works in its most basic form. The graphic is expanded to clearly show the cells constituent parts. Although, in reality this cell can take on a two main forms:

» Cylindrical: similar in style and look to a normal AA flashlight battery

» Prismatic: this is where the 5 different layers are sandwiched and protected in a thin ribbon, protected normally by an alloy pouch.

The car batteries can he recycled and used fur many more years in BESS [Battery Energy Storage System} to store energy at off peak times to reinforce the grid.

Fact

Discharge. When a lithium cell is discharging, the lithium-ions move from the negative electrode (anode) across the electrolyte (Viscous chemical mixture) to the positive electrode (Cathode), producing the energy that powers the battery.

Charge. When the battery is charging the chemical mix of metal oxides, the positive electrode sends over some of its lithium-ions, which flow through the electrolyte to the negative electrode (anode) and remain there. The battery consumes and stores energy in this way, during this charging process.

The growth of EV’s on our roads will release the world from its stranglehold on carbon based fuels.

Fact

Cost, safety and energy density

From a manufacturing perspective, there are four key areas of uncertainty. All have a direct impact on price, safety and cost to produce and cost to market. One thing is absolutely certain, that battery costs will fall over the coming years with technological advances, increased production, modular and charging standardisation.

What influence will the cost of developing differing types of batteries, have on the developing EV market? What will be the scale of progress over the coming decade and what are some of the key obstacles that will need to be addressed?

» Cell chemistry development – evolving technology

» Rare earth material availability – key components in lithium battery technology

» Uncertain scale of consumer and commercial demand

» Policy direction from national and local governments

» Without government aid, there is a limited amount of research and development capacity. This can affect long term reduction in cost, higher density capacity and overall cost of EVs in general.

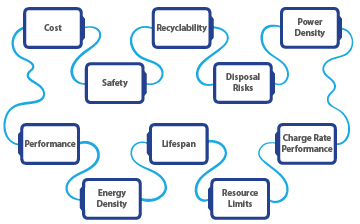

To highlight these and many other issues that all manufacturers of EV batteries must address as a matter of course, the following diagram (figure 8) reveals ten critical battery characteristics that allow positive battery design, innovation, safety, performance and environmental requirements to be met exponentially.

Rapid battery recharging is quick and easy. There are more than 5000 rapid chargers in the USA and almost 2000 in the UK.

Fact

Thanks for your blog, nice to read. Do not stop.