Main variants of lithium battery technology

The recent boom in lithium-ion based battery innovation is powered by the industry thirst to conquer major battery technology compromises. There are six aspects in the technical areas of battery design that are competing with one another. Ideally, all 6 aspects of each battery chemistry would score high (outer edge of each chart) in all six areas. The closer to the centre of each chart a parameter is set, the lower its performance is in that area.

» Performance: Peak power at high and low temperature, thermal management and state of charge analysis.

» Lifespan: Measured in how many years the battery will operate within the design parameters and the number of charge cycles.

» Specific power: The amount of power the battery can store per kg of weight. The higher the safe speed of energy discharge, the higher the power rating.

» Specific energy: The amount of energy the battery can store per kg of weight.

» Cost: The challenge over the coming years is to reduce battery manufacturing costs, by R&D progress and scale of manufacturing to produce higher volumes. Economies of scale are key in this area as the market grows.

» Safety: The safety characteristics built into the design of the chemistry used in each technology. Currently LFP and NCA offer the highest degree of safety, although solid state batteries promise even higher levels of safety in the near future. There are design countermeasures built-in such as intumescent boxes or cell pack coatings to prevent the spread of heat or flame.

Range

EV range depends on the quantity and variant of batteries used, the type and weight of vehicle, weather, road terrain and performance requirement. The real-world range of production electric vehicles in 2019 ranged from 62 miles (100km) to 340 miles (540km) specifically the Tesla Model S 100D [16].

All electric cars are fitted with a display that forecasts range, normally taking into account the way the vehicle is being driven, and what ancillary electrics (such as air conditioning or heated seats) the battery is operating. Nevertheless, since influences on battery drain can vary on route, the estimate can differ from the actual range. The display simply allows the driver to make educated choices about driving speed and whether or where to stop at a charging point on the way.

Lifespan

All lithium-ion batteries used in EVs will degrade slowly over time, particularly if they are frequently overcharged, though, this may take several years before it would be noticeable.

In 2015, after 10 years of data and feedback from dealers and drivers, Nissan indicated that only 0.01 percent of batteries needed to be replaced through failures or problems and in all cases, only due to externally imposed damage [17]. Both Tesla and Nissan have vehicles that had already travelled in excess of 124,274 miles (200,000 km), with no significant battery issues. In fact, the vast majority of manufacturers now guarantee their battery packs for a minimum of between 80,000-100,000 miles (130,000km – 160,000km) or 8 to 10 years, such is the confidence in their battery life.

Future battery innovation

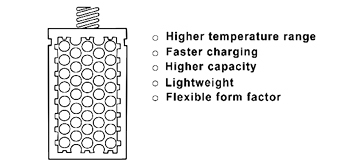

Innovation in lithium-ion battery technology continues to develop at a fast pace. Innovations include material development for cathodes and anodes, new cell coatings and protection, electrolyte development, processing of electrodes and new design and innovation in the assembly of batteries. Other developments include innovative liquid and solid electrolytes, leading to new solid-state batteries and graphene technology including future super capacitors, forecast to replace batteries in the future.

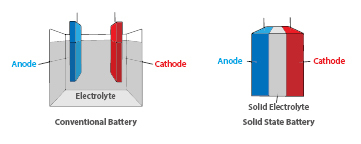

Solid state batteries

Solid state battery technology is viewed as the Holy Grail of stored power. It has been under development by research institutes and battery manufactures for more than a decade. There has not been a major breakthrough yet in achieving economically viable performance on a commercial scale.

Solid state batteries use much lighter polymers to store and discharge energy. This technology promises far lighter and less costly power storage that potentially negates the use of rare earth metals and environmentally damaging manufacturing processes. In the past, solid state battery prototypes had not demonstrated the ability to be scaled-up commercially to employ in EVs [18]. This obstacle has meant that solid state battery research has seen huge investment in time and capital to ensure that these new batteries offer significantly advanced performance over traditional lithium-ion batteries. But the most important criteria, is the target to create a solid state battery, that is economically viable to manufacture and practical enough to be scaled up for use in EVs, to survive the future move towards carbon free transport.

Super capacitors

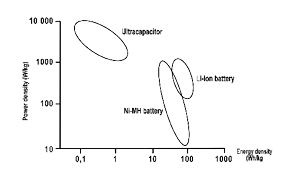

Super Capacitors, or Ultra Capacitors as they are also known, potentially have significant advantages over batteries. They are faster to charge, much lighter, non-toxic and safer. But at the moment, they are not quite ready to compete head on with traditional lithium-ion battery types [19].

Like batteries, super capacitors are a type of energy storage device and they have been gaining a growing reputation over the past few years. In effect, the super capacitor is a hybrid capacitor/battery, but in reality, quite different from both. Unlike batteries, super capacitors store energy like a conventional capacitor, electrostatically, rather than chemically like a battery.

Nonetheless, compared to batteries, super capacitors store less energy than a similar mass battery in their present guise. Though they can release energy much faster than a battery, since the discharge is not reliant on a chemical reaction happening. The other great benefit is that super capacitors can be charged many more times than batteries with little or no degradation. In fact, under controlled testing, they have been known to exceed more than one million charge and discharge cycles, mainly because no chemical or physical reaction is occurring during a charge or discharge cycle. Once perfected, this technology holds great promise for the future of EVs.

Graphene technology

Since graphene was first discovered in a laboratory at the UK’s Manchester University in 2004, developments have moved fast towards applications to replace steel (it is 10 times stronger than steel but 1000 times lighter than a sheet of paper of the same dimensions) [20]. But by far one of the most promising developments has been its potential for ultra-high-density batteries for EVs. The main advantage of using graphene for a battery electrode is that it has a high surface area and yet can be just one atom thick. To make this concept practical, the layers of graphene must be packaged into a 3D object. This means that in future, car bodies and doors, could also be the cars batteries. This technology is still in its infancy. It is not expected to reach market for at least a decade.